Hydraulic cement might seem like a reliable fix for concrete cracks, but it rarely holds up in the long run. In this article, we’ll explain why it often fails to fill cracks effectively—and introduce better alternatives like CrackWeld®, ElastiPoxy®, and our RadonSeal DIY injection kits that provide lasting waterproof protection and structural repair.

Why Repairing Concrete Cracks Is Important for Your Home

Concrete is known for its strength and durability, which is why it’s widely used in construction. However, like all building materials, concrete can deteriorate over time—especially when cracks begin to form in slabs, floors, foundations, or walls.

If you’ve spotted a crack, your first instinct might be to run to the hardware store and grab a bag of hydraulic cement. But not so fast. While hydraulic cement has its place in construction, it’s usually not the best choice for repairing concrete cracks, sealing leaking joints, or patching structural holes.

Whether your goal is to stop water intrusion, restore structural integrity, or improve appearance, there are far more effective concrete crack repair solutions available. Let’s take a closer look.

What Is Hydraulic Cement?

Hydraulic cement is a type of cement that sets and hardens when it reacts with water. In fact, nearly all modern concrete structures use hydraulic cement in some form. It begins as a dry mix and, once combined with water, undergoes a chemical reaction called hydration that causes it to cure into a solid mass.

In everyday use, the term “hydraulic cement” usually refers to quick-setting, cement-based patching compounds. These products are often modified with additives to accelerate curing, improve surface adhesion, or help stop active water leaks. They’re commonly sold in powder form at hardware stores and are mixed with water just before application, then applied using a trowel or putty knife.

Why Hydraulic Cement Is a Poor Choice for Concrete Crack Repairs

At first glance, using hydraulic cement to fill cracks in concrete may seem like a fast and easy fix. But while it sets quickly and feels rock-solid, hydraulic cement is rarely the right solution for long-term crack repair. Here’s why:

Rigid and Inflexible

When hydraulic cement cures, it forms a hard, inflexible mass. However, concrete naturally expands and contracts with temperature changes, moisture, and settling. Cracks and joints in concrete are dynamic—they move. Because hydraulic cement lacks flexibility, it cannot accommodate this movement. Even slight shifting can cause the repair to crack, separate, or fail prematurely.

Poor Adhesion to Concrete

Hydraulic cement does not bond well with existing concrete surfaces. This weak bond makes repairs vulnerable to water intrusion, efflorescence, and eventual breakdown. Some installers try to improve adhesion by chiseling a reverse “V” shape into the crack before application—but this is an added step that still doesn’t solve the fundamental bonding issue.

Limited Durability

Hydraulic cement patches often have a short lifespan. They’re susceptible to freeze-thaw cycles, heavy loads, and surface wear. Mixing precision also matters—too much or too little water during preparation can weaken the repair. Compared to modern polyurethane and epoxy products, hydraulic cement simply lacks long-term durability.

Unsightly Appearance

Hydraulic cement repairs rarely blend in. Cracks often need to be widened or “chased” with a grinder before the cement can be applied, which increases visibility. And because patching compounds differ in color and texture from the surrounding concrete, repairs often stand out—especially on floors, patios, or walls where aesthetics matter.

Why It’s Important to Repair Concrete Cracks Quickly

Not every crack in concrete is an emergency, but ignoring them can lead to bigger problems. Some cracks—especially in basement slabs, foundation walls, or retaining walls—can allow water intrusion, soil gases, or pests to enter your home. Over time, even minor cracks can widen, leak, or contribute to serious structural issues.

Here’s why prompt crack repair matters:

-

Moisture intrusion – Water seeping through cracks can cause mold growth, concrete deterioration, and damage to finishes like paint or flooring.

-

Radon gas infiltration – Soil gases like radon can easily pass through unsealed cracks and enter living spaces, posing health risks.

-

Pest access – Ants, spiders, and other insects often use cracks as entry points into your home or basement.

-

Trip hazards – Cracked walkways, driveways, and patios increase the risk of injury, especially for children and older adults.

-

Property value and resale issues – Visible cracks can scare off buyers or complicate real estate transactions. Unrepaired damage can also reduce curb appeal.

The sooner you repair a crack, the easier it is to prevent leaks, structural deterioration, or costly remediation down the road.

Common Causes of Concrete Cracks Around the Home

Concrete cracks are extremely common in residential construction. While not all cracks indicate structural problems, understanding what causes them can help you determine the right repair approach—and when to take action. Below are the most common types of cracks and their typical causes:

Shrinkage Cracks

These hairline cracks form as concrete cures and dries. As moisture evaporates, the concrete shrinks slightly, causing fine surface cracks. Shrinkage cracks are usually shallow and not a structural concern, but they can still allow water or gas infiltration if left unsealed.

Settling Cracks

These cracks occur when the soil beneath the slab shifts, settles, or was improperly compacted before pouring. Settling cracks are typically wider and more uneven. They may appear stepped or offset and can signal movement that requires attention.

Thermal (Expansion/Contraction) Cracks

Temperature changes cause concrete and the ground beneath it to expand and contract. This thermal movement can lead to irregular, meandering cracks—especially in exterior slabs like patios, driveways, and walkways.

Structural Cracks

These are the most serious and can indicate that the concrete element (such as a foundation or beam) is under stress or failing. Signs include cracks wider than 1/4 inch, horizontal cracks, or those accompanied by bowed walls, sticking doors, or sloping floors. A structural evaluation may be needed.

Cracks from External Forces

Heavy traffic, poor construction techniques, water pressure, nearby excavation, or tree root intrusion can all cause concrete to crack. These may appear suddenly and vary in size and pattern depending on the source.

Better Alternatives for Repairing Concrete Cracks

Hydraulic cement and off-the-shelf patching compounds may seem convenient, but they rarely provide lasting results. For a truly effective and permanent concrete crack repair, you need materials that bond strongly, allow for movement when needed, and hold up against moisture, weather, and wear.

That’s why we recommend specialized products designed for long-term performance—not just a quick cosmetic fix. Below are the best repair solutions for different types of concrete cracks, developed specifically to outperform conventional methods:

CrackWeld® Concrete Floor Repair Kits

Best for: Hairline cracks, shrinkage cracks, crazing, and narrow settling cracks in concrete slabs (<1/4″)

CrackWeld is a low-viscosity, two-part polyurethane crack filler that penetrates deep into the concrete and permanently bonds the slab back together. Unlike surface-level cement patches and urethane caulk, CrackWeld forms a high-strength, structural bond that won’t loosen or fail. It cures stronger than the concrete itself and prevents cracks from widening or “yawning” over time.

-

No grinding or chiseling required

-

Stronger than concrete itself

-

Ideal for garage floors, basements, patios, and slabs

-

Fast-curing for minimal downtime

If you’re looking for a seamless, nearly invisible repair that holds up under stress, CrackWeld is the go-to choice.

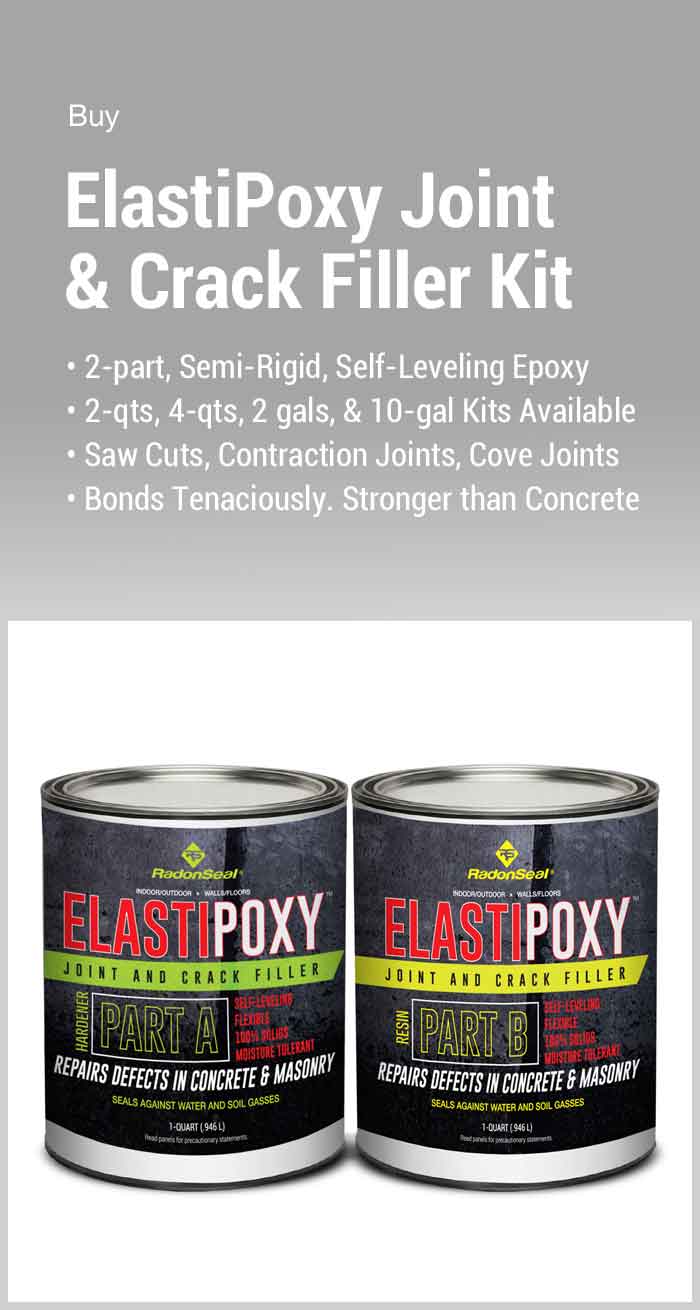

ElastiPoxy® Joint & Crack Filler Kit

Best for: Wide cracks (>1/4″), control joints, floor-to-wall joints, and cracks in block walls

ElastiPoxy is a two-part, self-leveling epoxy that forms a semi-rigid yet resilient repair. It allows minor movement while protecting the surrounding concrete from stress and further cracking. It can even be mixed with sand to create an epoxy-based mortar for patching block walls, filling mortar joints, or sealing leaking tie rods.

-

100% solids epoxy—no shrinkage

-

Flexible yet tough under load

-

Can be applied to horizontal or vertical surfaces

-

Excellent adhesion and water resistance

Choose ElastiPoxy when you need flexibility, durability, and moisture protection in wider or more complex joints.

Foundation Crack Repair Kits (DIY Injection Systems)

Best for: Wall cracks in poured concrete foundations, basement walls, and retaining walls

These kits use professional-grade polyurethane or epoxy injection materials to fill cracks from the inside—sealing the entire depth of the wall and stopping active water leaks. Designed for DIYers but used by professionals, these kits offer permanent waterproofing and structural repair in one.

-

Fills the entire depth of the crack

-

Stops water seepage for good

-

Available with either expanding polyurethane (for leaking cracks) or structural epoxy (for stabilization)

-

Easy step-by-step instructions

Hydraulic cement can only seal the surface—our injection kits seal the whole crack from front to back, making them far more effective and long-lasting.

Why These Products Work Better

Unlike hydraulic cement, our repair solutions:

-

Penetrate deeply and bond with the existing concrete

-

Remain flexible or semi-rigid, so they can tolerate natural expansion and contraction

-

Provide waterproofing and long-term strength

-

Blend better aesthetically, especially on floors and exposed concrete

If you want a repair that lasts, resists movement, and actually improves the condition of your concrete—not just covers it up—our crack repair systems are the right choice.

🧱 Concrete Crack Repair Comparison Chart

| Product/Method | Best Use Case | Flexibility | Durability | Limitations |

|---|---|---|---|---|

| Hydraulic Cement | Quick patching of surface voids | ❌ Rigid | ⚠️ Short-term | Poor adhesion, cracks again with movement |

| Urethane Caulk (e.g., SikaFlex) | Surface cracks, joints, non-structural | ✅ Flexible | ⚠️ Moderate | Shallow penetration, low structural strength |

| CrackWeld® | Hairline to 1/4″ floor cracks | ❌ Rigid | ✅ Long-term | Not for moving joints; sets very hard |

| ElastiPoxy® | Wide cracks, joints, block walls | ✅ Semi-rigid | ✅ Long-term | Requires mixing; needs sand for wall repair |

| DIY Injection Kits | Foundation wall cracks (poured concrete) | ✅ Flexible / Expanding | ✅ Long-term | Designed for poured concrete walls only |