Why Your Garage Floor Needs a Sealer

A garage floor sealer is one of the simplest and most cost-effective upgrades you can make to protect and extend the life of your concrete slab. Left unsealed, concrete floors absorb oil, road salts, moisture, and de-icing chemicals that lead to stains, cracks, efflorescence, and long-term deterioration. By applying a concrete garage floor sealer or sealant, you stop damage before it starts—keeping your garage cleaner, drier, and more valuable.

In this guide, we’ll explain the different types of garage floor sealers, how to choose the right one for your needs, and the exact steps to prep and seal your floor for long-lasting results.

What Damages a Concrete Garage Floor

These days, a garage is much more than a place to park your car. It may serve as a workshop, gym, storage area, or even an extension of your living space. A dirty, cracked, or stained garage floor not only makes the space less usable, it can also lower your home’s resale value. According to real estate trends, a well-kept garage is now considered a valuable upgrade for homeowners and can even help sell a house faster.

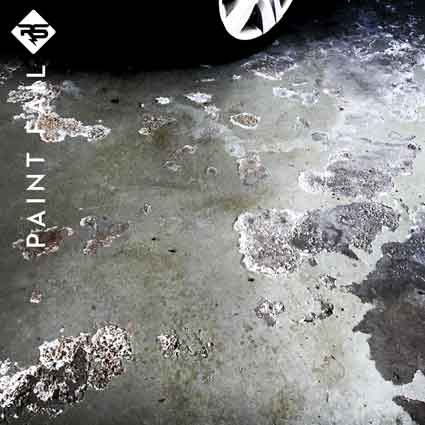

But concrete is a porous material that’s vulnerable to many forms of damage if left unsealed. Over time, a garage floor can deteriorate due to:

-

Engine fluids – Oil, transmission fluid, and antifreeze seep into pores, leaving stains and breaking down concrete.

-

Deicing chemicals and road salts – Brought in by vehicle tires, these chemicals penetrate the surface, creating freeze–thaw cycles that cause spalling and cracking.

-

Ground movement – Soil shifts can lead to cracks and uneven slabs.

-

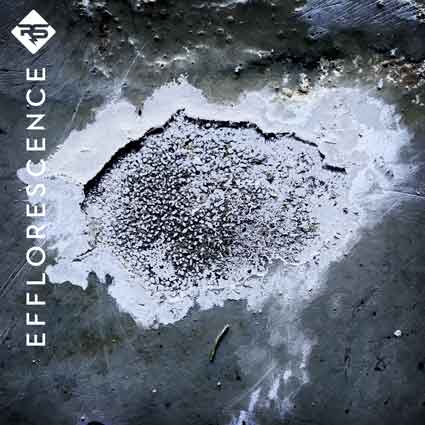

Missing vapor barrier – Many garage floors were poured without one, allowing water vapor to wick up through the slab, leading to damp spots, efflorescence, and mold.

-

Wicking water – Concrete naturally pulls in moisture, which shows as dark patches or white mineral deposits.

-

Water vapor permeation – Moisture rising from the ground can cause coatings like epoxy to blister, peel, or fail.

-

Sweating concrete – Warm, humid air condenses on cool concrete, creating slick, damp floors and accelerating deterioration.

Sealing your garage floor addresses these issues by reducing moisture infiltration, blocking chemicals, and strengthening the concrete against daily wear.

How to Choose the Best Garage Floor Sealer

Not all garage floor sealers work the same way, and choosing the right one depends on your floor’s condition, how you use the garage, and whether you plan to paint or coat the surface later. The wrong choice can lead to peeling, hot-tire pickup, or trapped moisture, while the right concrete garage floor sealer will protect your slab for decades.

Here are the main types of sealers and how they compare:

-

Penetrating Sealers (Silicate, Siliconate, Silane/Siloxane) – Soak into the concrete, harden the slab, reduce water absorption, and remain breathable. They won’t peel or change traction, making them the most reliable long-term choice for garages with moisture concerns.

-

Acrylic Sealers (Water- or Solvent-Based) – Form a thin film on the surface that adds sheen and light stain resistance. They are economical and quick-drying but may peel or scuff in high-traffic areas.

-

Epoxy, Urethane, and Polyaspartic Coatings – Build a high-build surface layer that provides gloss, color, and strong chemical resistance. They work best on dry slabs but can fail if moisture vapor is present.

When deciding which product to use, first test your floor for moisture, then weigh your priorities: low-maintenance durability, decorative finish, or maximum chemical resistance.

Why Seal Concrete Before Painting or Epoxy Coating

If you plan to finish your garage floor with paint, epoxy, or another surface coating, deep-sealing the concrete first is essential. Floor paints and coatings—sometimes called garage floor sealants—form a surface film that traps water vapor rising through the slab. Without mitigating this moisture transfer, even the strongest coatings can bubble, peel, or crack as moisture builds up underneath.

A good penetrating concrete garage floor sealer solves this problem by reducing water vapor transmission while keeping the concrete breathable. This creates a stable, long-lasting base for paints, stains, and epoxy coatings—so they bond properly and don’t fail prematurely.

💡 Pro Tip: Not all penetrating sealers are paintable—always check with the manufacturer before applying a coating on top.

That’s why contractors and DIYers alike apply RadonSeal® or LastiSeal® before painting or installing a garage floor coating: they waterproof and harden the concrete internally, while leaving the surface ready for adhesion.

Thinking about epoxy? Before you decide, read our guide: Garage Floor Sealer vs Epoxy Coating: Which Is Better for You?

DIY WATERPROOFING

Penetrating Sealers for Garage Floors

__________

These selected garage floor sealer are the top performers for sealing garage floors. They are all penetrating, waterproofing products that seal concrete internally. They are all slip-resistant and do not alter surface appearance. They are water-borne, solvent-free, user- and environment-friendly, allowing for safe use indoors without noxious fumes.

How to Choose the Best Garage Floor Sealer

When selecting a garage floor sealer, consider how you use your garage, your slab’s moisture levels, and whether you plan to paint or coat the floor afterward. Each of our penetrating sealers offers unique advantages:

RadonSeal® Deep-Penetrating Concrete Sealer

Best for Moisture Control and Preparing for Coatings

-

Penetrates up to 4″ deep to chemically seal against capillary water seepage, water vapor, and efflorescence.

-

Strengthens weak or porous garage slabs and protects against road salts, freeze–thaw, and spalling.

- Provides excellent waterproofing against both negative- and positive-side water pressure.

-

Leaves the surface paint-ready, making it ideal to use before applying epoxy, paints, or levelers.

-

Permanent results. Long-term protection against moisture and humidity problems.

👉 Use if: You need maximum moisture protection and plan to finish the floor with epoxy or paint.

LastiSeal® Brick & Concrete Sealer

Best All-Purpose Choice for Waterproofing and Stain Resistance

-

Polyester-based sealer that penetrates 2–4″ and internally plugs concrete pores.

-

Provides excellent waterproofing against positive-side water pressure.

-

Strengthens concrete to prevent dusting, cracking, and surface wear.

-

Superior stain resistance compared to RadonSeal; compatible with most coatings (except latex and silicone).

👉 Use if: You want a durable, versatile sealer that both resists stains and remains compatible under paints and coatings.

DryWay® Water-Repellent Concrete Sealer

Best for Water-Repellency, Stain Resistance, & Easy Cleaning

-

Penetrates closer to the surface, repelling water, oil, and chemical spills.

-

Keeps surfaces cleaner and makes seasonal cleanup faster.

-

Provides up to 10 years of protection against oil stains, road salts, and de-icing chemicals.

-

Not designed for use under paints or floor coatings.

👉 Use if: You want maximum water-repellency and stain protection and don’t plan to paint or coat your garage floor.

| Product | Best For | Paintable / Coating Compatible | Key Benefits |

|---|---|---|---|

| RadonSeal® Deep-Penetrating Concrete Sealer | Moisture control, efflorescence, weak slabs | ✅ Yes | • Penetrates up to 4″ • Stops negative-side moisture & efflorescence • Strengthens concrete • Ideal base under epoxy/paint |

| LastiSeal® Brick & Concrete Sealer | All-purpose waterproofing + stain resistance | ✅ Yes (except latex/silicone) | • Seals 2–4″ deep • Resists stains & salts • Hardens surface, reduces dusting • Versatile for many surfaces |

| DryWay® Water-Repellent Concrete Sealer | Water-Repellency and easy cleaning | ❌ No | • Repels water & chemicals • Resists stains & salts • Up to 10-year service life • Best for low-maintenance floors |

DIY WATERPROOFING

Cleaners & Etchers for Garage Floors

__________

Commercial-Grade concrete cleaning and etching products used before the application of penetrating sealers, concrete paints, and epoxy coatings. Made stronger than store bought cleaners and also user-friendly!

How to Clean & Prep the Concrete Before Sealing

Proper preparation is the most important step before applying any garage floor sealer, sealant, or coating. Skipping prep is the #1 reason sealers and coatings fail. Follow these steps to make sure your concrete is ready:

Clean the Surface Thoroughly

Oil, grease, old paint, and efflorescence must be removed before sealing. Not all cleaners are created equal—using the right product makes the job faster and more effective.

RadonSeal offers professional-grade cleaners designed for garage floors:

-

Universal Concrete Cleaner & Degreaser (Eco-Friendly): Removes oil, grease, fluids, dirt, and grime.

-

Efflorescence Cleaner: Tackles heavy efflorescence, lime, and rust deposits.

-

PowerEtch Concrete Etcher & Cleaner: Etches and opens the pores while removing light efflorescence, rust, tannins, and red clay stains.

Create the Right Surface Profile (CSP)

Garage floors often have a smooth, machine-troweled finish, which makes it difficult for sealers or coatings to absorb or bond properly. For best results:

-

Penetrating sealers require a CSP of at least 1 (acid-etched, 0–3 mils).

-

Paints, epoxies, and levelers work best on CSP-1 to 2 (mechanically profiled, 3–10 mils).

To achieve the correct profile:

-

Mechanical prep (grinding or shot-blasting) opens the pores on dense, hard-troweled slabs.

-

Chemical etching is the most common method. Traditional muriatic acid is cheap but hazardous, while RadonSeal’s PowerEtch offers a safer, easier-to-use alternative that opens pores, reduces pH, and improves coating adhesion.

👉 Not sure if your floor is porous enough? See our guide: Do I Need to Etch My Concrete?

Repair Cracks & Surface Defects

Cracks not only look unsightly but also expand over time, leading to spalling, crumbling, and water seepage. Repairing cracks before sealing ensures a durable surface.

RadonSeal offers permanent repair solutions:

-

CrackWeld® Concrete Floor Crack Repair Kits – Deep-fills and bonds hairline to wide cracks.

-

ElastiPoxy® Joint & Crack Filler Kits – Flexible and durable filler for control joints, cracks, and spalls.

Unlike caulks or hydraulic cement, these kits bond the concrete together for long-lasting results, preventing cracks from propagating through paints or coatings.

Garage Floor Sealer FAQs

Will a garage floor sealer interfere with epoxy or paint adhesion?

Some sealers are not paintable because they leave a surface film that prevents coatings from bonding. However, RadonSeal® and LastiSeal® are penetrating concrete garage floor sealers that absorb into the slab rather than forming a film.

-

RadonSeal®: Fully paintable and the best choice if you plan to apply epoxy, paint, or levelers.

-

LastiSeal®: Generally paintable and compatible with most coatings (except latex or silicone).

-

DryWay®: Not recommended under paints or coatings, since it’s designed as a long-term water-repellent surface treatment.

👉 For best results, etch the concrete with PowerEtch before sealing to ensure good porosity and strong adhesion of paints or epoxies.

How do I remove paint that is chipping from my garage floor?

There are two main methods:

-

Chemical removal: Apply a concrete-safe paint stripper and scrape away softened paint.

-

Mechanical removal: Use a floor grinder, sander, or pressure washer to strip the coating.

Often, a combination of both methods works best.

How long do I have to wait before adding carpet or paint after sealing?

RadonSeal penetrates deep into the concrete and may purge minerals for several days. To be safe:

-

Paint, levelers, or adhesives: Wait 10 days after sealing.

-

Loose carpet or mats: Can be placed back down after about 2 days, once the concrete is dry.

Which product stops efflorescence and paint failure on stem walls?

Use RadonSeal® Plus. It penetrates the concrete, blocks water migration, and prevents efflorescence from forming, which in turn stops paint from bubbling or peeling.

How can I reduce humidity inside my garage?

High humidity often comes from water vapor moving upward through the slab. Applying RadonSeal reduces vapor transmission and cold air infiltration, helping to regulate humidity and protect tools, wood, and stored items.

Which garage floor sealer is best for easy cleaning after winter?

If your priority is stain resistance and easier cleanup, choose:

-

LastiSeal® – Penetrates deeper, fills pores, and provides long-term waterproofing + stain resistance.

-

DryWay® – Repels water, engine fluids, and road salts, making spring cleanup much faster.

👉 Both are penetrating sealers, not surface garage floor sealants, so they provide longer-lasting protection without peeling.

What’s the difference between a garage floor sealer and a sealant?

Homeowners often use the terms interchangeably, but they’re not the same:

-

Sealant: Usually a surface coating (like paint or epoxy) that forms a film but can trap moisture.

-

Sealer: A penetrating treatment that soaks into the concrete, hardens it, and remains breathable.

For long-lasting protection, a penetrating garage floor sealer is the better choice. If an epoxy coating or sealant is the plan, seal with RadonSeal first to reduce moisture.

How long does a garage floor sealer last?

It depends on the product and usage:

-

RadonSeal® – Permanent, deep-penetrating protection against water vapor and efflorescence.

-

LastiSeal® – 15+ years of waterproofing and stain resistance with normal use.

-

DryWay® – Up to 10 years of surface stain and water repellency before re-application is recommended.

Ready to Seal Your Garage Floor?

A garage floor sealer is one of the most effective ways to protect your concrete against moisture, stains, and long-term damage. Whether you’re planning to paint or epoxy the surface, or just want a cleaner, more durable floor, choosing the right sealer makes all the difference.

-

RadonSeal® – Best for moisture control, strengthening and hardening your slab, and as a base before epoxy or paint.

-

LastiSeal® – A versatile choice for waterproofing, surface hardening, and stain resistance.

-

DryWay® – Superior stain resistance and easy cleaning for low-maintenance garages.

👉 Take the next step and protect your investment: Shop Garage Floor Sealers »