Before painting, coating, installing carpeting or wood flooring on concrete floors make sure to test the moisture vapor transmission rate and alkalinity of the concrete slab. The calcium chloride test kits and pH test kits from Vapor Score make it easy and affordable for homeowners and flooring contractors. Considering the potential damages from trapped moisture in $100s or $1,000s, testing the water vapor infiltration is inexpensive insurance.

The test kits are complete and include:

- Anhydrous calcium chloride test dish

- Orange plastic dome

- Alkalinity pH test kit

- Testing procedures with a calculation formula

- MVER calculator is also available online.

Concrete Moisture Test

The concrete moisture test kits measure the Moisture Vapor Emission Rate (MVER) from the surface of a concrete slab. Also called dome test kits, they use the Anhydrous Calcium Chloride Vapor Emission Method and conform to ASTM (American Society for Testing and Materials) F-1869 and F1907-04.

As a desiccant, anhydrous calcium chloride absorbs moisture from the air. Place the small container with calcium chloride on the concrete floor and cover it by the plastic dome. The heavy-duty orange dome helps prevent tripping accidents. After 60-72 hours, cut out the calcium chloride dish. The vapor transmission rate is calculated from the weight difference of the calcium chloride dish at the beginning and the end of the test. You must use a highly accurate gram scale (sold separately).

For new construction, ASTM requires 3 kits for the first 1,000 sq. ft. and at least 1 kit for each additional 1,000 sq. ft. The temperature of the surface should be in the range of 50-70°F. The internal conditions in the room should be 40-60% humidity and 65-85°F.

Alkalinity pH Test Kit

New concrete is highly caustic and may attack adhesives, paints, and flooring materials. But as the concrete ages and reacts with carbon dioxide in the air, the alkalinity of its surface gradually decreases.

ASTM requires that a pH test be performed along with every moisture test. Flooring manufacturers insist on pH testing before the installation of flooring. One pH test kit, which conforms to ASTM F710, is included with each vapor test kit.

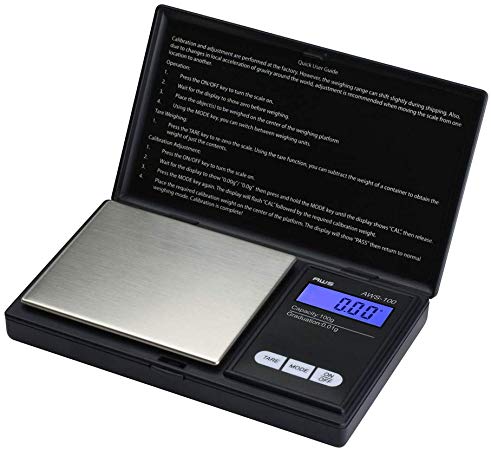

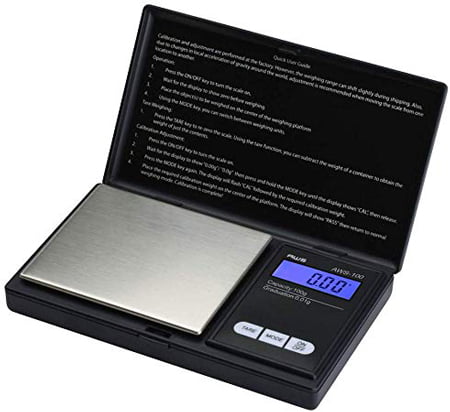

Digital Electronic Scale

This highly accurate digital gram scale measures the amount of moisture absorbed by calcium chloride test kits. It features an accuracy of 0.01 grams with a capacity of 100 grams.

This compact pocket scale features a checkbook-size design with a large backlit LCD to make the display easy to read. Push buttons offer multiple units and functions with full control such as switching modes grams, ounces, troy ounces, and pennyweights.

It is a durable scale with a protective cover. Its smooth stainless steel weighing surface is easy to clean.

Homeowners will find this affordable but precise scale handy for multiple purposes around the house like weighing cooking portions or mail.

Shipping and Pricing

Orders are normally shipped within 24 hours and delivered within 2 to 5 workdays to the lower 48 states.

Based on shipping to the lower 48 states. For expedited shipping or shipping to other states and Canada, please inquire first by e-mail or telephone.

ASTM requires 3 kits for the first 1,000 sq. ft. and at least 1 kit for each additional 1,000 sq. ft. for new construction.

Why Did My New Beautiful Floor Fail?

Moisture emissions from concrete and its pH level often make or break the success of any floor covering installation.

Concrete is very porous. Water vapor from the concrete and the ground below oozes through the pores and gets trapped under any coating or flooring on the surface. The vapor pressure can build up and lift epoxy coating or vinyl tiles. High moisture will buckle hardwood floors. Trapped moisture can cause molds, which also attack wood flooring.

New concrete is very caustic with a typical pH of 11 to 13. The alkalis from concrete, mainly lime, the natural by-product of its curing, and hydroxides of sodium and potassium attack and break down adhesives, paints, vinyl tiles, carpet padding, etc.

When the alkalis attack the plastic backing of carpeting, it may cause “plasticizer migration” into the concrete, resulting in a noxious smell from the concrete even after the flooring has been removed. (Instead of removing the slab, seal it with RadonSeal Deep-Penetrating Concrete Sealer!).

The Plastic Sheet Test

This test has been used for more than 50 years. The ASTM E 1907 describes the test procedure which is still accepted by some flooring manufacturers.

Use an 18 in. (460 mm) square transparent polyethylene sheet at least 4 mils (0.10 mm) thick. Tape it to the concrete slab with a 2 in. wide duct tape – all edges must be sealed tight. Leave the plastic sheet in place for at least 16 hours. Then, remove the sheet and check for the presence of moisture – droplets on the underside of the sheet or on the concrete, a darker color of the concrete surface.

Years ago, when flooring adhesives were more moisture-resistant than these days, this test was sufficient before installing flooring. However, this test does not provide a reliable indication of the floor moisture condition. 16 hours is not long enough to reflect the moisture movement from the bottom to the top of the slab but it largely indicates the conditions of the surface. It may also reflect condensation on the surface instead of the moisture flow through the slab.

The Limits on Vapor Transmission and pH

Many flooring manufacturers now insist that there must be a vapor retarder sheet underneath the slab and set the vapor transmission limit at 3 or 4 lbs/1,000 sq. ft./24 hours. That means less than ½ gallon of water may pass through an area of 1,000 sq. ft. per day. The flooring manufacturers’ warranties become void if MVER or alkalinity exceed their specified limits.

However, a manufacturer reports that 96% of tested slabs exceed the limit. Some slabs may be very porous due to the concrete mix or a high water/cement ratio. Very porous slabs exceed 10 or even 15 lbs/1,000 sq. ft./24 hours.

The flooring warranties also require that the alkalinity of the concrete surface may not exceed pH 9.

The concrete must be at least 1 month old before installing flooring but many contractors conservatively wait for several months.

Concrete May Pass the Concrete Moisture Test Now but the Flooring May Fail Later

Once the concrete surface is covered, water cannot evaporate and the moisture levels equalize through the slab. This may also bring to the surface more alkalis from inside the concrete.

When the concrete slab is exposed to water from the ground, it gradually deteriorates. The pores get larger and the concrete passes more water vapor and even wicks up liquid water.

Consequently, the vapor transmission and alkalinity tests cannot offer a 100% guarantee of long-term successful floor covering installation. There is still some uncertainty. No wonder that the flooring manufacturers set the limits conservatively low.

Even if your concrete floor passes the moisture and alkalinity tests, consider sealing it with RadonSeal Concrete Sealer now to permanently reduce water vapor transmission and alkalinity of the surface.

How to Reduce Moisture Transmission and Alkalinity

There are epoxy or hybrid coatings and special membranes for the surface, but moisture and alkalinity will over time break down any coating.

Most flooring contractors just put down a plastic sheet before installing hardwood flooring.

Plastic sheets or membranes trap all moisture rising through the concrete, which may cause molds and mildew and musty odors. But this takes time and will usually outlast the contractors’ 5-year warranty on the flooring.

The best solution is to deep-seal the concrete slab with RadonSeal Penetrating Concrete Sealer. It reacts deep inside the concrete, expands inside the pores, cures, and seals them permanently. And as it passes through the surface, it neutralizes lime and alkalis, reducing the alkalinity of the surface. It hardens the surface but does not change its profile – leaving the concrete suitable for paints, adhesives, thinset, etc.

For best results, wait at least 10 days and seal the slab again with Ion-Bond Armor Subsurface Sealer. It also seals deep inside the concrete but has smaller molecules and bonds with RadonSeal. The surface remains suitable for paints or adhesives. This sealer combination was successful on slabs exceeding 14 lbs/1,000/24 and is easy to apply by contractors or homeowners.