Concrete is a durable and long-lasting material that is often used in construction for its strength and stability. However, like all materials, it is not immune to damage, and one of the most common issues that homeowners and property managers face is the appearance of cracks in their concrete surfaces. While it may be tempting to drive to the nearest hardware store to pick up a bag of hydraulic cement patching material, don’t start the car just yet. While hydraulic cement is useful in a variety of construction projects, it’s usually not an effective option for repairing concrete cracks, water-proofing joints and seams, or patching holes. Whether you are trying to stop water, provide structural support, or just improve the aesthetics of the concrete, there are far superior crack repair alternatives available. Let’s take a closer look…

What is Hydraulic Cement

Hydraulic cement is a type of cement that sets and hardens when mixed with water. Almost all concrete structures that you come in contact with are technically made with hydraulic cement – it begins as a wet mix that uses water to initiate the chemical process called hydration.

In everyday use, the term “hydraulic cement” is used to describe quick-setting, cement-based patching compounds that are often modified with additives that accelerate curing, stop water, or adhere to surfaces more effectively. These concrete patching compounds are available in most hardware stores and are typically sold in powder form. Once mixed with water it can be applied to surfaces with a trowel.

Repairing Concrete Cracks with Hydraulic Cement

While it may seem quick and easy to simply fill in cracks with hydraulic cement or concrete patch, this is not a good long-term solution. Here are some reasons why repairing cracks with hydraulic cement is my not be a good idea:

Rigid Cure:

When hydraulic cement cures, it becomes a hard and inflexible mass. However, as concrete naturally expands and contracts due to temperature changes and other factors, cracks will expand and contract as well. Additionally, certain joints or seams (e.g. floor-wall joints, contraction joints) are dynamic joints that are designed or expected to move.

When hydraulic cement is troweled into or over a crack or joint, its rigid cure is not able tolerate movement. While cement patches have a very high compressive strength, they have poor tensile strength, flexural strength, and bend strength. Even the slightest movement will cause the patch to crack and fail.

Poor adhesion:

Adhesion is the ability of a material to bond or stick to a surface, and it is an important factor in the effectiveness of a concrete crack repair. When hydraulic cement is used to patch cracks, it does not form a strong bond with the existing concrete. This leads to a weaker repair that will not hold up over time. Additionally, the joint between the two materials is susceptible to water infiltration and efflorescence, which can cause further damage and weakening to the repair.

To improve the adhesion of hydraulic cement, it is often recommended to chisel an inverted “V” shape into the slab before applying the troweling the hydraulic cement into the crack. This is necessary to help hold the repair material in place and compensate for the poor adhesion value.

Limited durability:

The limited durability of hydraulic cement is an important consideration when choosing a crack repair material. The rapid hardening of the cement means that it does not have the same long-lasting durability as other types of crack repair materials. It’s particularly vulnerable to weather and heavy loads, freeze-thaw cycles, and other environmental factors that can cause degradation over time. Additionally, home mixing hydraulic cement is generally a less-than-precise process. Not enough water, too much water, and other imprecisions can reduce durability further.

Hydraulic cement repairs are ugly:

Cracks in concrete floors and walls may need to be “chased” or opened with a grinder before repair with hydraulic cement is possible. Hairline cracks, crazing cracks, and other very fine cracks would need to be made much larger before repairing them. If you are looking for a seamless crack repair (and who isn’t?), then making a crack bigger makes little sense. The impact on the aesthetics is significant.

Additionally, because of the different types of cement used in the original concrete and the patching material, it is likely the colors will not match, making the repair even more noticeable.

There are other, more effective products and methods for repairing cracks in concrete, spalls, leaking joints, and other defects that are worth considering. These methods will likely provide a stronger and longer-lasting repair.

Importance of Quickly Repairing Concrete Cracks

While the is no need to panic if you find a crack in your concrete slab or basement wall, ignoring it is not wise. Some cracks should be repaired more quickly than others. For example, cracks in basement slabs and foundation walls can allow water to seep in and cause damage. This can lead to mold growth, which can be harmful to both the structure and the people occupying it. Soil gases, such as radon, can easily pass through cracks and into homes and occupied spaces. Additionally, bugs and other pests may find cracks as an open invitation to your home. Cracks in concrete surfaces can create tripping hazards and increase the risk of injury. Unrepaired cracks in concrete can negatively impact the value of a property, and complicate real estate transactions.

Common Causes of Cracks Around the Home

It is important to note that concrete cracks are a very common occurrence. There are several reasons why concrete slabs may crack. Understanding these causes can help you identify and address the problem before it becomes too severe. Some more common types of cracks and their causes are:

- Shrinkage cracks: These cracks occur due to the contraction of concrete as it cures and dries. Shrinkage cracks are typically fine and hairline in nature, and are most commonly found on the surface of the slab. Shrinkage cracks are of no structural concern.

- Settling cracks: These cracks occur when the soil beneath the slab settles or compacts, causing the slab to sink and crack. They are often wider and more prominent than shrinkage cracks. Settling cracks may be uneven or stepped.

- Thermal cracks: These cracks occur due to the expansion and contraction of the ground due to temperature fluctuations. Thermal cracks are typically wider and more irregular than shrinkage cracks. They commonly have a meandering or jagged appearance.

- Structural cracks: These cracks occur due to the failure of the slab or foundation to support the weight of the structure. Structural cracks may be accompanied by other symptoms such as doors or windows that stick or fail to open or close properly.

- Cracks caused by external forces: Concrete may also crack due to external forces such as heavy traffic, poor construction practices, underground utilities, water pressure, or tree roots.

Alternative Methods for Repairing Concrete Cracks

There are several types of concrete crack fillers available and no product is best in all situations. Overall, the repair material and method you choose should be durable, have good adhesion properties, be able to accommodate movement when needed, and should also be as unnoticeable as possible.

Below you will find the best-rated concrete repair products for different cracks.

CrackWeld Concrete Floor Repair Kits – For narrow cracks in concrete slabs (<1/4″ to hairline). Ideal for shrinkage cracks, crazing, hairline, and settling cracks. No grinding or chasing needed! CrackWeld is a low-viscosity, 2-part, fast-curing, polyurethane crack filler that seeps deep into the crack and permanently welds it back together. CrackWeld provides superior adhesion strength and a bond that is stronger than concrete itself – so strong that it can prevent further movement or “yawning”.

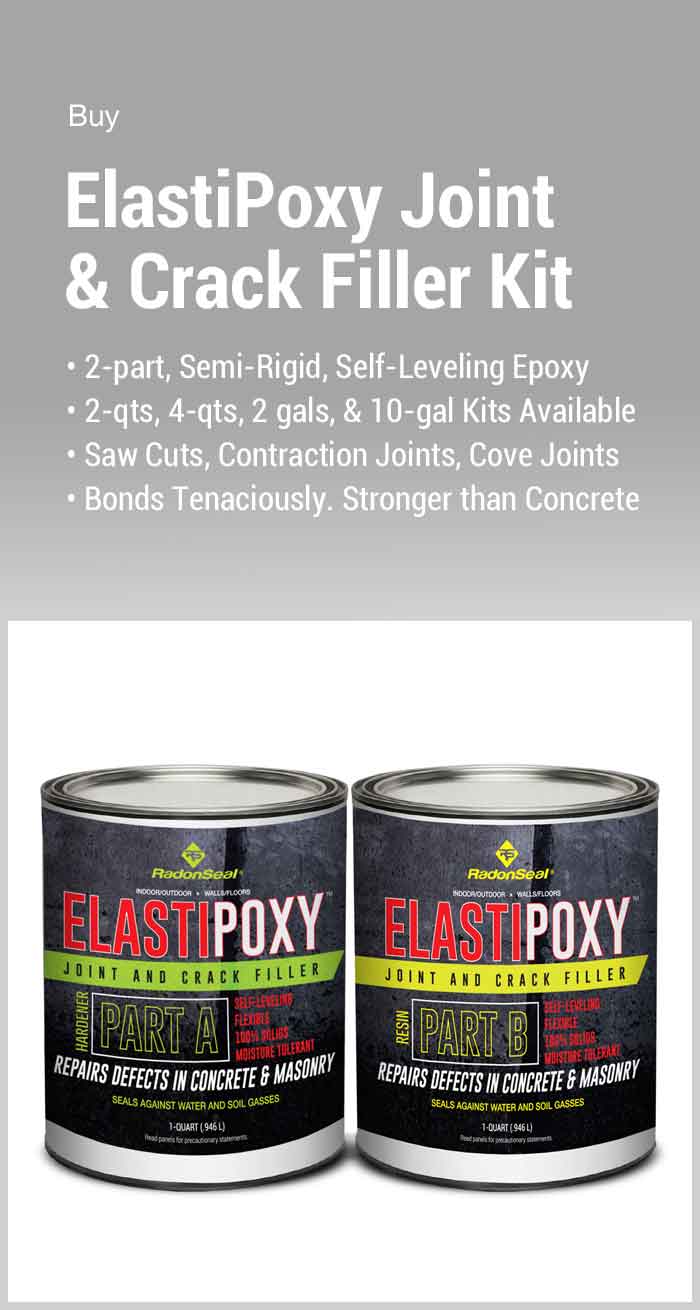

ElastiPoxy Joint & Crack Filler Kit – For wide cracks (>1/4″), saw cuts, contraction joints, and floor-to-wall joints. ElastiPoxy is a 2-part, 100% solids, self-levelling epoxy. When cured, ElastiPoxy forms a semi-rigid repair. This allows for minor movements the joint or crack, while still protecting the joint shoulders from damage. ElastiPoxy can also be used on walls to repair vertical cracks. Mix with sand to produce an epoxy-based mortar substitute to repair a block wall crack, fill mortar joints, or water-proof leaking form ties.

Do-It-Yourself Foundation Crack Repair Kits – For cracks in poured concrete foundation walls, basement walls, and retaining walls. The #1 crack repair kit for water-proofing and stabilizing cracks in concrete walls. Available with expanding polyurethane injection material or structural epoxy injection.

For detailed information on concrete crack repair methods, visit our CRACK REPAIR GUIDE.