No Reliable Power for Your Sump Pump? Use Water Instead!

It happens after every major storm. Scores of basements get flooded because there was no electricity for the sump pumps. Homeowners rush out to buy out all the puny backup sump pumps on store shelves. Battery-powered. But after the next big storm, some basements get flooded again – the batteries did not last or the cheap backup pumps failed.

During a severe thunderstorm or big snowmelt, you don’t want to worry about your sump pump (Top 10 reasons why sump pumps fail) and power outages or about the battery on your backup sump pump. You may be away while your basement floods and mold infestation starts in just a few days. The backup sump pump is your “last line of defense” against basement flooding and thousands of dollars in damages. Its reliability is critical!

For the highest possible reliability, get Hi & Dry Water-Powered Backup Sump Pump! It does not depend on electricity or batteries because it is powered by municipal water. And as long as the water is available, they can run infinitely! There is no impeller or motor – there are no rotating parts to break or wear off. No cleaning or maintenance is required.

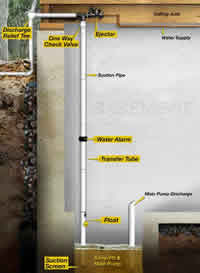

This simple and elegant design uses an old, well-proven principle. Pressurized water pushes through the pump and as it speeds up through a narrow Venturi nozzle, its pressure drops. This creates suction – that’s how they make vacuums in school labs. The emergency sump pump (“ejector”) draws water up from the sump pit and pushes all the water out through a discharge pipe.

What Makes Hi & Dry™ Water-Powered Backup Pumps Better?

Location, location, location! They are not submerged inside a filthy sump pit like other backup sump pumps. Hi & Dry™ pumps are mounted “high and dry” on the ceiling. They draw water from the sump pit by suction just like through a giant soda straw and push it out through a discharge pipe. This unique ceiling-mounted design has inherent advantages:

- THE HIGHEST PUMPING RATES (by far) in the industry.

- SUMP COVER – you can seal the sump against radon gas, vapor, and for children’s safety.

- FIT TODAY’S SMALL SUMP PITS (below 18″ diameter – even down to 10″).

- THE HIGHEST RELIABILITY – BACKED BY A 5-YEAR WARRANTY (unsurpassed in the industry).

- THE LONGEST SERVICE LIFE – estimated 25 years or longer.

Order Today!

Hi & Dry™ backup sump pumps are shipped directly from the factory to your door. Orders received by noon are normally shipped the same day and delivered by courier within 2 to 5 workdays within the lower 48 states. Shipped as a Pump Installation Kit including a water alarm and accessories.

Based on shipping by UPS to the lower 48 states. For expedited shipping or shipping to other states and Canada, please inquire first by telephone or e-mail. Regarding shipping, returns, and other terms, review our Commercial Terms.

30-DAY MONEY-BACK SATISFACTION GUARANTEE – If not completely satisfied, you can return the pump for a full refund of the price, excluding shipping, within 30 days of shipment. You must phone first for shipping instructions. When shipping the pump back (at your cost), you should purchase shipping insurance.

5-YEAR LIMITED WARRANTY – The pumps are warranted against all defects in material and workmanship for a period of five years from the date of shipment. You must phone first for shipping instructions. When shipping the pump back (at your cost), you should also purchase shipping insurance. We will either replace or repair the product, at our option and ship it back to you at no charge.

Complete Pump Installation Kits RB750 and HB1000

- Pump (ejector) made from heavy-duty polypropylene.

- Independent High Water Alarm with a 9 V battery and relay outputs.

- Hydraulic Float and Transfer Tube for hydraulic signal.

- One-Way Check Valve to prevent reversed water flow down into the sump.

- 3-ft. Flexible PVC Discharge Hose.

- Mounting Clamps and Screws.

- PVC Fittings to connect your suction and discharge piping.

- Cable Tie Straps.

- Suction Screen.

- Illustrated Instructions for DIY Installation

Which Pump Size Do I need?

Hi & Dry pumps have by far the highest pumping rates among water-powered emergency pumps due to their unique "ceiling-mounted" design. Highly efficient – one gallon of city water pumps out about two gallons of sump water.

The pumping rate of all pumps depends on municipal water pressure and the needed lift from the bottom of the sump pit to the discharge. The higher the water pressure, the higher the pump output. But the higher the lift, the lower the pumping rate although it does not decrease dramatically until above 15-ft.

Pumping Rates for Hi & Dry Pumps (10-ft. Lift)

| Pump Model | RB-750 | HB-1000 | CB-1500 |

|---|---|---|---|

| Water Pressure psi |

Sump Water Removed gallons/hour |

Sump Water Removed gallons/hour |

Sump Water Removed gallons/hour |

| 40 | 700 | 900 | 1,400 |

| 50 | 725 | 950 | 1,450 |

| 60 | 750 | 1,000 | 1,500 |

| 80 | 800 | 1,200 | 1,700 |

| 100 | 900 | 1,400 | 2,000 |

| Water Connection | 1/2″ or 3/4″ | 3/4″ | 1″ or 3/4″ adaptor (incl.) |

| Suction Pipe, Discharge Hose |

1″ | 1-1/4″ | 1-1/2″ |

| Typical Use | Residential – homes with common flows of sump water | Residential/Commercial – for high volumes of sump water | Commercial – buildings with very high volumes of sump water |

Please click on a pump model for details

RB-750: Residential – homes with common flows of sump water

| Water Pressure (PSI) |

Sump Water Removed gallons/hour |

| 40 | 700 |

| 50 | 725 |

| 60 | 750 |

| 80 | 800 |

| 100 | 900 |

Water Connection: 1/2″ or 3/4″

Suction Pipe, Discharge Hose: 1″

HB-1000: Residential/Commercial – for high volumes of sump water

| Water Pressure (PSI) |

Sump Water Removed gallons/hour |

| 40 | 900 |

| 50 | 950 |

| 60 | 1,000 |

| 80 | 1,200 |

| 100 | 1,400 |

Water Connection: 3/4″

Suction Pipe, Discharge Hose: 1-1/4″

CB-1500: Commercial – buildings with very high volumes of sump water

| Water Pressure (PSI) |

Sump Water Removed gallons/hour |

| 40 | 1,400 |

| 50 | 1,450 |

| 60 | 1,500 |

| 80 | 1,700 |

| 100 | 2,000 |

Water Connection:1″ or 3/4″ adaptor (incl.)

Suction Pipe, Discharge Hose: 1-1/2″

Do I Have Enough Water to Power the Pump?

If your primary sump pump has to handle lots of sump water, you will need a larger emergency pump. If interested, you can calculate the actual water inflow into your sump. IMPORTANT: Before selecting your pump model, you must first check that there is sufficient water pressure and flow for the pump size (the “Bucket Test“)!

Pre-Assembled Accessories for an Easy Installation

You can avoid the hassle of shopping for suitable accessories. Save time and money! The accessories are factory-assembled units and you just have to attach them to the pump with a wrench.

Models RB750-EZ and HB1000-PRO come with these pre-assembled accessories:

- Brass Ball Valve to shut off the water to the unit.

- Brass Dual Check Valve to help meet local backflow prevention requirements

- Brass Push-fit Male Adapter so you just push in the water supply pipe, copper or PEX.

Also included is a Brass Push-fit Tee to install into an existing water supply pipe. No soldering is needed – just push the pipes in.

The standard Dual Check Valve is a generally accepted backflow prevention device. It contains two internal check valves for redundancy, or a “fail-safe” condition, which allows water to flow in only one direction. Meets ASSE listed #1024, CSA Certified B64.6.

Although you have to buy the PVC suction pipe and water piping locally, our pump kits are quite complete compared to other pumps. Cost Comparison of Accessories with the competition.

Models RB750-EZ-V and HB1000-PRO-V are the same except that the backflow preventer is a Dual Check Valve with Vacuum Breaker Vent as approved by the State of Illinois. The standard dual check valve has the added protection of a downstream vented vacuum breaker as required in some jurisdictions. Meets ASSE listed #1012, CSA Certified B64.3. State of Illinois Approval #890-1140(k).

A 10-ft. length of tubing for drainage into the sump is included.

You should first check with your water company on any special requirements for backflow prevention.

Accessories for the commercial CB-1500 model:

Dual Check Valve (1") for CB1500 – meets plumbing code standards (ASSE #1024 Certified; UPC, IAPMO Approved; CSA Standard B64.6). Thread it directly onto the pump. It also acts as a union. No extra shipping cost when ordered with the pump.

Integral Atmospheric Vacuum Breaker (1") for CB1500 – To satisfy very strict local codes. Approved by all backflow prevention authorities (ASSE listed 1001, IAPMO listed, CSA certified). Shipped factory-installed on the pump inlet. Note the pump must be installed horizontally and the AVB must be at the highest point. The discharge pipe from the pump must be sloping and self-draining or the water would run out of the AVB valve. No extra shipping cost when ordered with the pump.

Feedback from Customers |

|---|

|

“… great pump! I installed the RB-750 which was quick and easy. It works like a champ! …” – Robert T., IL “… shortly after I put it in our neighborhood lost power. I was sitting on my door step hearing my sump turn on and had such a good feeling knowing I didn’t have anything to worry about. Since then I have installed 2 others in my neighbors houses…” – Bob, Eden Prairie MN “… purchased my HB-1000 last November and I am attaching a couple of pictures showing exactly how I installed my pump. I tested the performance of the pump and was blown away. It only takes about 20 seconds for the pump to remove all the water in my pit, almost as fast as the main pump …” – Tom O., MI “… raining cats and dogs for several hours and I am sitting here in the dark, writing this email by flashlight, because we are without power. I can’t begin to describe how wonderful it is to hear the valve on the Hi & Dry Pump activate … it has sat dormant and been inactive for 3 years. …” – Chaz B., NY See Customers’ Feedback with Tips and Photos from Homeowners and Plumbers. |

What Makes Hi & Dry Pumps the Best-in-Class?

These are the most powerful and most reliable pumps on the market – backed up with a 5-Year Manufacturer’s Warranty, unsurpassed in the industry. Note that some plumbers promote their other pumps to earn a commission. Insist on the best pump performance and reliability!

Most of the advantages just result naturally from the unique ceiling-mounted design which cannot be matched by the old inside-the-pit design:

- HIGHER PUMPING RATE – Pumps placed in the sump pit have to push up to the discharge not only the sump water but also all the municipal water after it has expanded and lost its pressure in the Venturi nozzle. Hi & Dry backup pumps, being mounted on the ceiling, let the city water flow right through a horizontal discharge pipe and have to pull up only the sump water. This results in a much higher pumping rate – about double the pumping rate of the other pumps.

- FITS IN SMALL PITS – The only solution for today’s smaller sump pits, even as small as 10″ in diameter. Other pumps with their mechanical floats need at least 18″ in diameter.

- SUMP PIT COVER – The sump pit can be covered and sealed against water vapor and radon gas. Just caulk around the discharge pipe penetration through the cover. Other pumps with their bulky in-the-pit designs do not allow the pit to be easily covered, which is also a hazard to children and toys!

- ALARM INCLUDED – High water alarm with output relays is included. This loud 85 dB alarm lets you know that the backup pump is running and you should check the power supply or the primary pump. Although an alarm is required in some states, it is not included with other pumps (value $30). You can connect it to your security system or even an auto-dialer – set it up to call your cell phone.

- BACKFLOW PREVENTION – Pumps located down in the sump are susceptible to backflow. There is a column of water standing in the discharge pipe above the Venturi nozzle, as well as in the suction pipe held above a check valve. Somebody may open a hydrant down the street or the water pressure suddenly drops and the dirty sump water may be siphoned into the city water piping. Homeowners are supposed to add a backflow prevention device, which can be more expensive than the pump itself. The Hi & Dry main ejector valve has a solid rubber diaphragm that reliably isolates sump water from the municipal water, and a patented integral check valve that closes the main valve drip-tight by using the pressure of municipal water – the city water cannot flow backward. More obviously, when mounted on the ceiling with suction and discharge pipes empty, any backflow suction would just suck in air through the discharge pipe. Nevertheless, we also offer backflow prevention devices to satisfy local regulations.

- WATER HAMMER RESISTANCE – Other pumps have solenoid shutoff valves whose sudden closing often causes water-hammer. You may have to buy a water hammer arrestor. Hi & Dry pumps use soft-closing diaphragm shutoff valves which usually avoid water-hammer.

- DRAINS THE PIT – The suction pipe reaches the bottom of the sump pit and the pump empties the entire pit in each cycle. The ejector runs for a full 15 to 45 seconds (adjustable). Other backup sump pumps have mechanical floats with limited travel of several inches and empty the pit only partially. This means frequent pump cycling and shorter service life.

- NO ENTANGLEMENTS – Hi & Dry suction pipe and float need less space and avoid interfering with the primary pump or its float inside the pit, which is the cause of many pump failures.

- STAYS CLEANER, LASTS LONGER – The Hi & Dry pump is not submerged in the grimy sump water or corrosive salts from water softeners. No buildup of deposits and no corrosion. Maximum reliability and service life – estimated at least 25 years (vs. 5 years for sump pumps).

Backflow Prevention is About Our Safe Drinking Water

Every water company receives each month several calls from homeowners complaining about “blue water” from their faucets. They and perhaps also their neighbors have been drinking their own toilet tank water which has been colored by toilet bowl cleaner! Instead of a “plumbing code approved” toilet flush valve, they had bought a cheap one.

If a nearby fire hydrant is turned on or a water main breaks, the sudden loss of water pressure may cause “back-siphonage” and draw contaminated water into the potable water system. If your neighbor is using a garden hose to fill a swimming pool or to spray pesticides on his lawn, it may end up in your drinking water during a sudden backflow. And according to a US EPA study, a majority of homes have a water cross-connection to a health hazard.

In spite of regulations and building codes on backflow prevention, many products sold in stores to trusting homeowners do not meet them. Conspicuous among them are the old-school water-pressure pumps located in the sump pit. Their vertical discharge pipe and suction pipe are filled with sump water and they are likely to contaminate drinking water during a sudden loss of water pressure. The homeowners might be exposed to lawsuits for contaminating the city’s drinking water.

Their manufacturers state that the homeowner must buy a backflow prevention device but it is well hidden in Instructions. Liberty Pumps recommend an RPZ Backflow Prevention Device (Reduced Pressure Zone), which costs more than the pump itself, restricts water flow to the pump and requires annual certification (about $60–80 each year). However, most plumbers ignore it.

Set-Up of the Hi & Dry Emergency Sump Pump

The pump operation is fully automatic – it works whether you are home or away. The backup pump has its own float switch, which activates the pump when the water level in the sump pit rises too high – above the level normally allowed by the primary sump pump. This also activates an audible high water alarm to let you know that you have to check the primary sump pump and its power supply. The alarm is a must but other manufacturers do not include it.

SUCTION PIPE – The suction PVC pipe (not included) reaches down to above the bottom of the sump pit and is connected to a check valve (included) just below the pump.

DISCHARGE HOSE – A flexible discharge hose (included) takes the water from the pump through the basement wall to a separate discharge, which is the recommended setup. In case the discharge pipe freezes up, the included pop-up pressure relief valve will spill the water onto the backyard, allowing the backup pump to still operate. If the pump discharge leads to the municipal sewer, leave an air gap of at least 1-inch to protect against backflow.

Alternatively, the discharge hose can be connected to the main discharge pipe from the primary pump using a T-connector (included). In this case, install the pop-up valve on the main discharge pipe to protect against freeze-up. Make sure that your check valve above the primary pump is in good working order to prevent backflow into the sump pit.

ADJUSTABLE HYDRAULIC FLOAT – This hydraulic (not mechanical) tethered float switch is not dependent on electricity or a battery. Its activation elevation is fully adjustable. It is a sophisticated grapefruit-sized On-Off switch to start or stop the pump that will not allow water to wastefully “bleed.” To help with the limited space inside the sump pit, the minimum needed lift of the float is only about 1-inch. It does not need to fully drop down to its lowest position to turn the pump off. It is connected to the pump by flexible pressurized tubing that is clipped onto the suction pipe. There is an adjustable timer screw on the pump which allows you to adjust how long the pump works after the float drops in each pumping cycle as needed to empty the entire pit (typically set at 20-30 seconds).